diondo linacsystems

Uncomprimising Insight for Demanding Applications

As industrial components grow in complexity, size, and material density, conventional X-ray computed tomography (CT) systems often reach their limits. High-Energy CT using a linear accelerator (LINAC) offers a powerful solution.

Linac systems providing high-energy photons—typically in the 6 to 9 MeV range—penetrate thick-walled metallic or composite structures that would otherwise be opaque.

The result is detailed volumetric data, essential for defect detection, dimensional inspection, and material analysis. From large nickel-alloy turbine blades to additively manufactured copper components to welds on power generation systems, Linac CT provides the necessary imaging clarity for confident decision making.

|

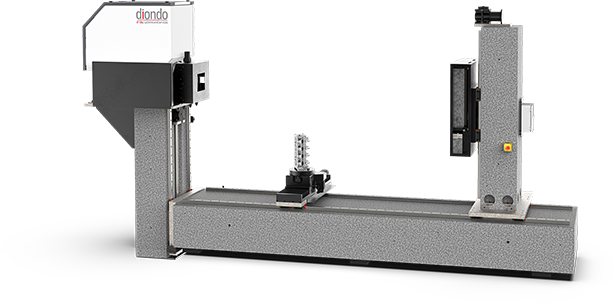

Lab Linac System |

Maximum Efficiency and Value for Money |

The Ultimate for Large-Format Scanning |

Optimized for Long Samples | |

|---|---|---|---|---|

| Sample Diameter | ||||

| Sample Height | ||||

| Sample Density | ||||

| Versatility | ||||

| Footprint | ||||

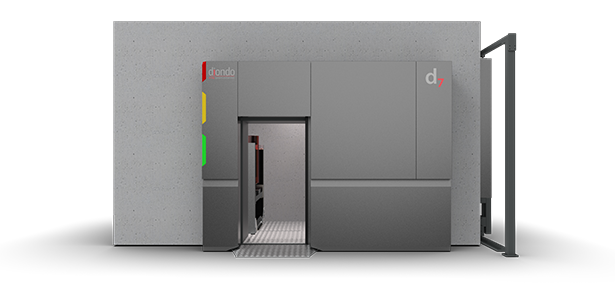

diondo d7

High-Performance Linear Accelerator CT System for Analyzing & Testing of High-Density Components

The linear accelerator CT system diondo d7 is the most powerful CT system of the product family and suited for analyses of high-density components,

...

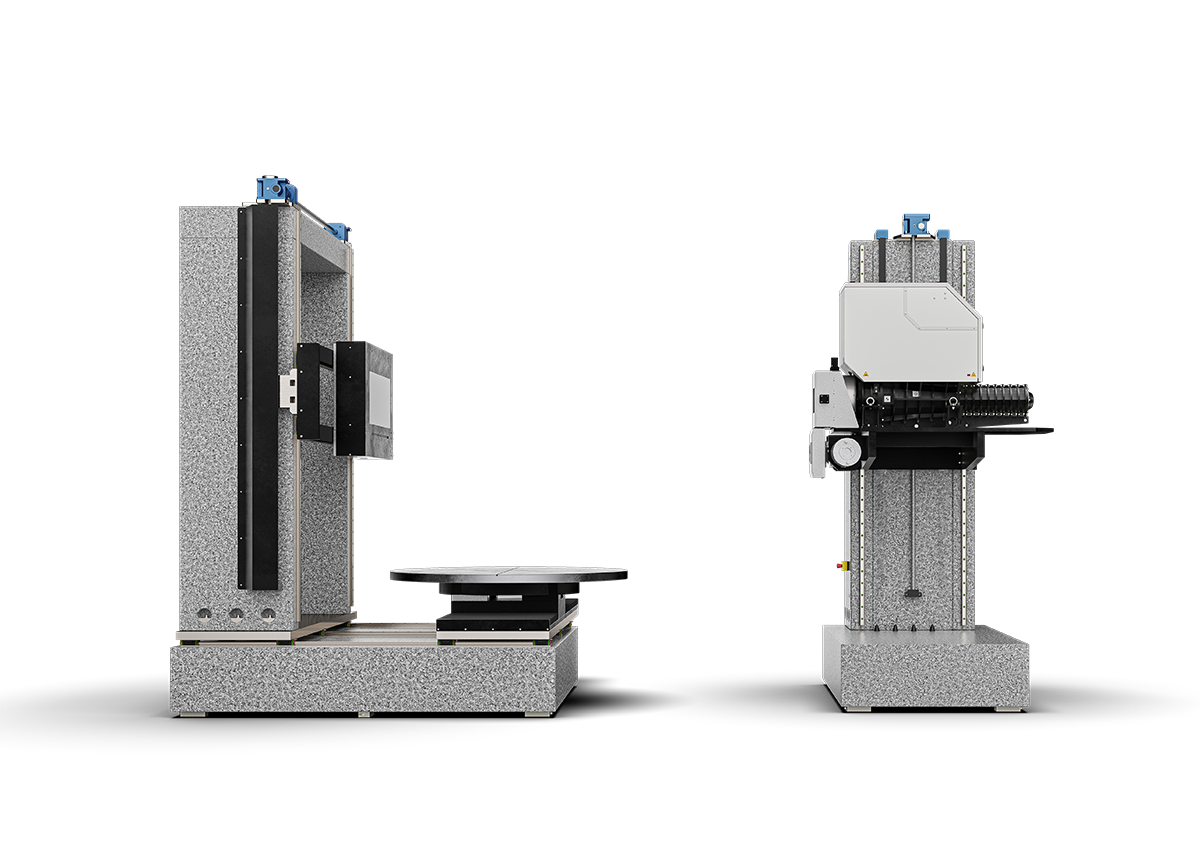

diondo d7 nanos

Special solutions: X-ray and CT Systems for individual applications

The linear accelerator CT system diondo d7 is the most powerful CT system of the product family and suited for analyses of high-density components (engine, crankcases, stators, turbine blades, etc.) from titanium, copper, steel or thick-walled aluminium.

The focus of the application of such powerful CT systems are predominantly component analyses to detect any manufacturing or material defects, as well as the review of shape and wall thickness of the test objects.

diondo d7 collosus

The Ultimate for Large Scale Scanning

The diondo d7 colossus is the ultimate solution for scanning oversized samples. Delivering unmatched penetration power and scan volumes, it enables previously unimaginable applications to be tackled with ease.

Moreover, the use of cutting edge detector technology facilitates high efficiency, whilst its innovative split design provides installation flexibility, despite the system's formidible sample capacity.

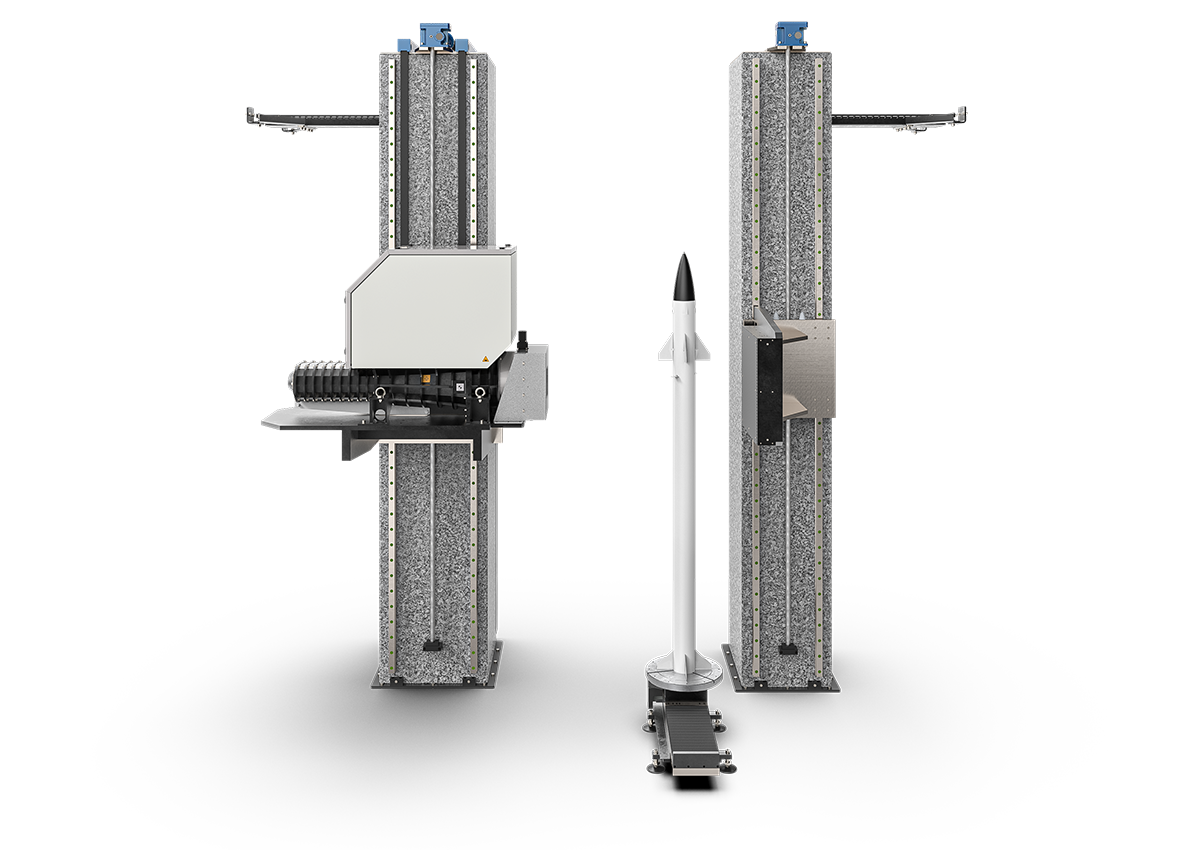

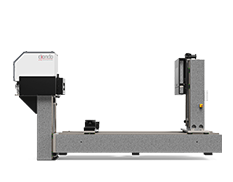

diondo d7 zenith

Designed for the Longest Samples

The diondo d7 zenith is a linac CT system dedicated to very long samples, and has been reduced to the essentials with reliability, footprint and cost in mind.

Extremely tall objects can thus be inspected comprehensively and efficiently, without for example recurring homing runs or unevenly stitched partial volumes. Options are available for extended object diameters, either by using particularly

large detectors or additional axes for further field of view extensions. Durable spindles and the solid granite construction guarantee long-term reliable performance.

Decades of Innovation

The Pioneers of MeV Imaging

diondo's roots are in MeV imaging - our team built Europe's first cone beam linac scanner in the early 1990s.

Dedicated Facilities for Preassembly & Factory Acceptance Tests

XXL MeV Bunker

These possibilities reduce the scale of on-site work and enable demonstrations as well as a potential period of operation before the customer site is ready

Customer Approved Quality

Western Market Leader in MeV Systems

With numerous customer installations spread across the world, diondo is the clear leader in linac industrial imaging.

Hands on Experience

MeV Scan Service

diondo can readily conduct application tests and has extensive practical expertise on linac CT given its daily use in the scan service department.

d

d d7 nanos

d7 nanos d7 colossus

d7 colossus d7 zenith

d7 zenith