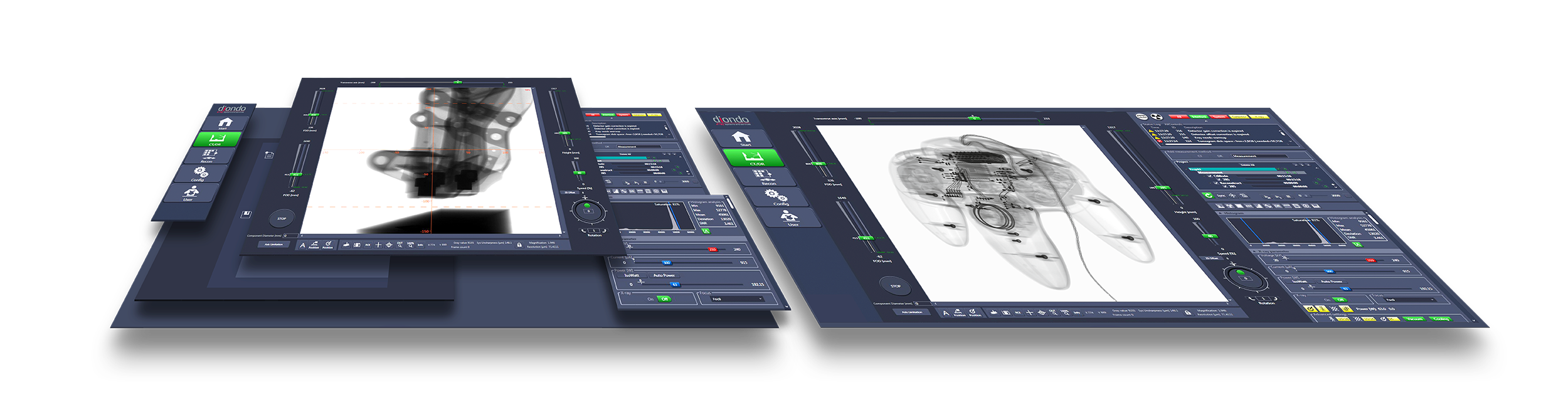

diondo diControl

3D X-ray Computed Tomography Software

Navigate Complexity with Ease

Discover a world of diverse possibilities with just one software package – your tailored solution for a variety of needs, whether in the industrial sector or research field. Our software is noted not only for its versatility but also by its user-friendly design, allowing you to achieve excellent results without significant effort.

diondo diControl

3D X-ray Computed Tomography Software

Unlock Potential: Seamless, Limitless, Effortless.

Benefit from an ever-expanding range of functions, inspired by close collaboration with our customers. This dynamic enables us to perfectly tailor the software to your individual needs, ensuring you always get the most out of your data. With minimal training, our solution allows you to work effectively and achieve high-quality results. And for the experts among you, the configurable interfaces and open interfaces offer even more possibilities.

High Efficiancy

By combining batch processing with stateof- the-art automation, scan sequences can be executed automatically, seamlessly extending across your system components (e.g. different X-ray sources), guaranteeing significant time savings.

User-Friendliness

Experience the ultimate in user comfort with our combined imaging and reconstruction software. Our intuitive sequential menu system and numerous automation features eliminate complex processes, enabling excellent scan results even with minimal training effort.

Limitless Flexibility

Enjoy unrestricted access to all images and data, and benefit from the possibility to implement custom scanning sequences. Our solution opens the door to a world of possibilities.

Individual Workflows

Integrate different components and create customized scan templates. Our solution also supports a wide range of post-processing and analysis workflows, by offering numerous output data formats (Raw, Tiff and DICONDE) and automatically generating VGL files.

User Aids

Simplify Your Life with Smart Solutions.

Developed to meet the requirements of modern production environments, our software offers a simple and intuitive user interface that significantly simplifies the

scanning process. Through innovative automations, comprehensive support, and precise alert systems, our software efficiently guides the operator to

achieve optimal scanning results - with minimal effort.

Our software aims to eliminate potential sources of error, extend the lifestime of your valuable machine components, and ensure consistently high image quality. With this solution by your side, you not only save valuable time but also costs.

diControl Feature Overview

Many Features, even more Possibilities

Combined Imaging and Reconstruction Software

Unrestricted Access to all Images and Data

Various supported Output Formats (Raw, TiFF, DICONDE)

Multilingual User Interface

Multiple User Levels

Digital Machine Logbook

Collision Protection

Integrated Webcams

CT Imaging

Basic Modules

- Multipoint Correction for the reduction of ring artifacts

- Automatic Focus Drift Correction to reduce blurring caused by the thermal expansion of the X-ray tube

- Multiple Rotation Modes for different speed-precision tradeoffs: Continuous - Stop in Motion - Stop and Go

- Generic or Custom Projection Filters for optimizing image quality

- Field of View Extensions [FoV] for seamless detection of even the largest objects

- Limited Angle Scan helps with scanning very large objects and reduces scanning duration

Add-On Modules

- Helix-CT for long objects and improved image quality

- Dual Helix combines the advantages of FoV Extension and Helical CT

- diPlanar for scanning high-aspect ratio samples using laminography trajectories

- Ultra Wide FoV Extension for scanning the very widest samples

- Multi-Line for the reduction of scatter artifacts

Reconstruction

Basic Modules

- Preview for optimal adjustment of the reconstruction parameters

- Generic or Custom Tomogram Filters for optimizing image quality

- Data Reduction skipping projections, reducing resolution and background segmentation

- Multi-Recon for direct comparison of different reconstruction parameters

- Inline Reconstruction enables reconstruction to start during data acquisition, so reconstructed volume is ready moments after the scan completion

- Artifact Reduction

- Ring artifacts

- Image noise

- Truncation artifacts

- Metal artifacts

- Beam hardening [BHR]

- ROI Recon for data volume and reconstruction time savings data

- Automatic Creation of VGL Files for easy import of reconstructed data

Add-On Modules

- Scan Enhancement effective reduction of beam hardening and scattered radiation effects

- diScatter to reduce image artefacts from scattered radiation

- Creation of VG-Recon-File for use in alternative, offline reconstruction

Digital Radiography

Basic Modules

- 1:1 Mode avoid missing defects due to reduced resolution

- Crosshair for better orientation and easy positioning of the object in the center

- Live Image Filtering to see the improved result immediately

- Generic or Custom Filters to individually optimize the image quality

- High Dynamic Range [HDR] enables the display of a wider range of brightness and contrasts to make defects more visible

- Image Sequence Capturing to record dynamic processes

- Pseudo Colors false-color representation to recognize every detail

- Grayscale Histogram Display overview of the grayscale distribution to optimize scan parameters

- DR Toolbox Measurement

- Line profile

- Angle measurement tool

Add-On Modules

- CNC Measurement high-precision measurement

- DR Stitching for high-resolution DR images of large objects

- Statistics Box for evaluating the grayscale values within defined ROIs

- DR Analysis Tool for tile-by-tile OK / Not OK classification of a sample

Quality Control

Basic Modules

- Health Monitor for monitoring all system components

- Scan Report for automatic documentation of all measurements

- Measurement History for automatic documentation of all scan reports

- Daily Check for automatic checking of image quality and measurement capability

Add-On Modules

- Metrology Mode for highest precision measurements

- Temperature Monitor with additional documentation as PDF

- Environment Monitor monitoring temperature and humidity with additional documentation as PDF

- ASTM & SMPTE Tools integrated and fully automated implementations of ASTM 2597 + AITM6-7007, ASTM 2737 guidelines

Automation

Basic Modules

- CT Batch Processing to carry out several measurements without further intervention by the operator

- Detector Correction automatic execution of detector corrections for each measurement

- Projection Selection automatic selection of the number of projections

- Tube Power Selection automatic selection for maximum resolution and minimum time

Add-On Modules

- Macro Execution automatic execution of a VG macro immediately after reconstruction or at a later time

- Time-Controlled Warm-Up to optimise the availability of beam time

- Smart Collimator Control automatic trimming of the beam cone depending on the detector distance

Special Tools

Add-On Modules

- External Trigger for communication and timing triggering of different components or processes

- User-Defined Trajectories for specific requirements, such as locally optimized image quality or reduced radiation exposure

- Batch Parameter Studies for measurement studies with CT parameter variation

- di4D for flexible reconstruction of different points in time of a process

- diZoom for high-resolution scans of flat objects

- diAspect Variable Projection-Density