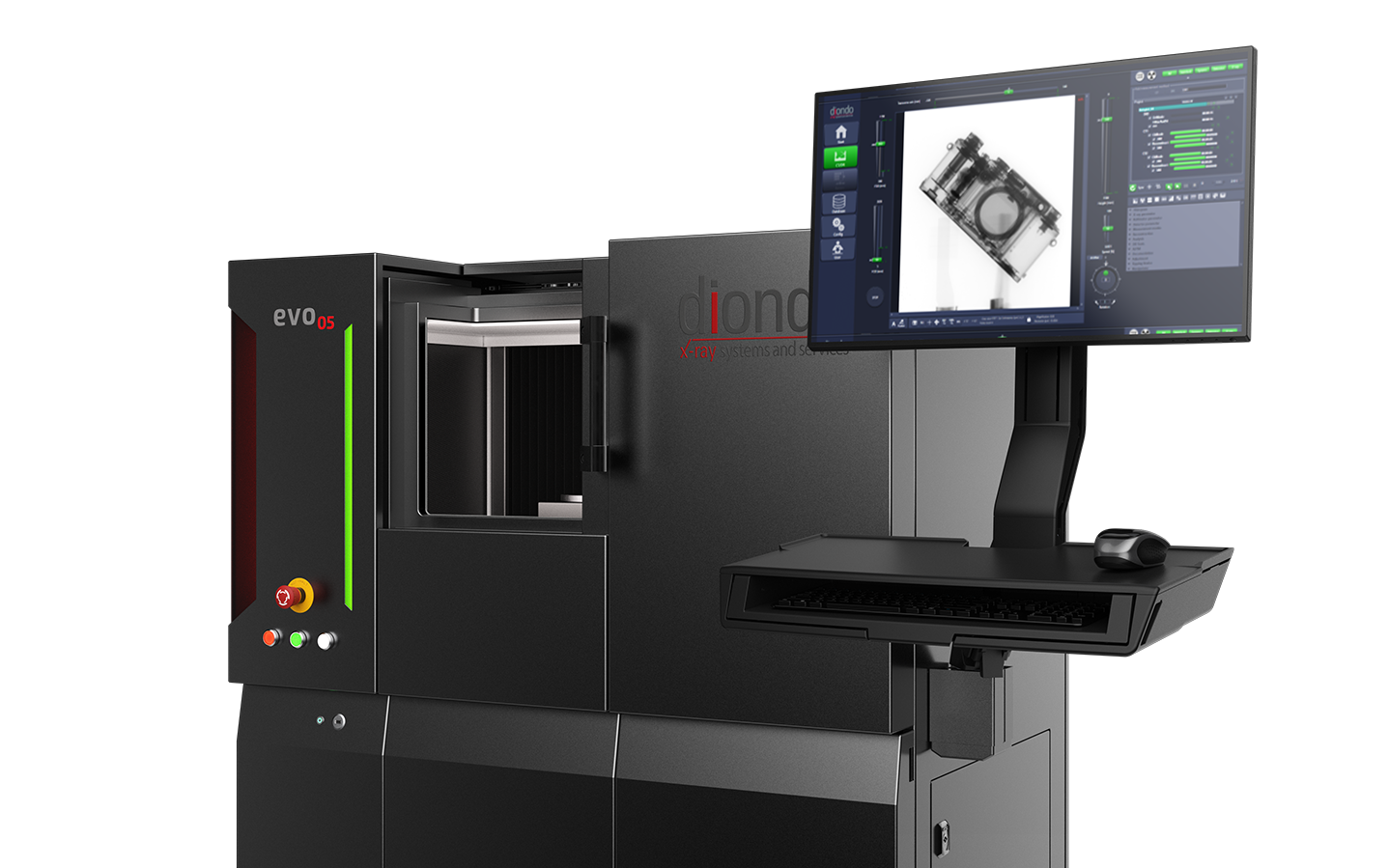

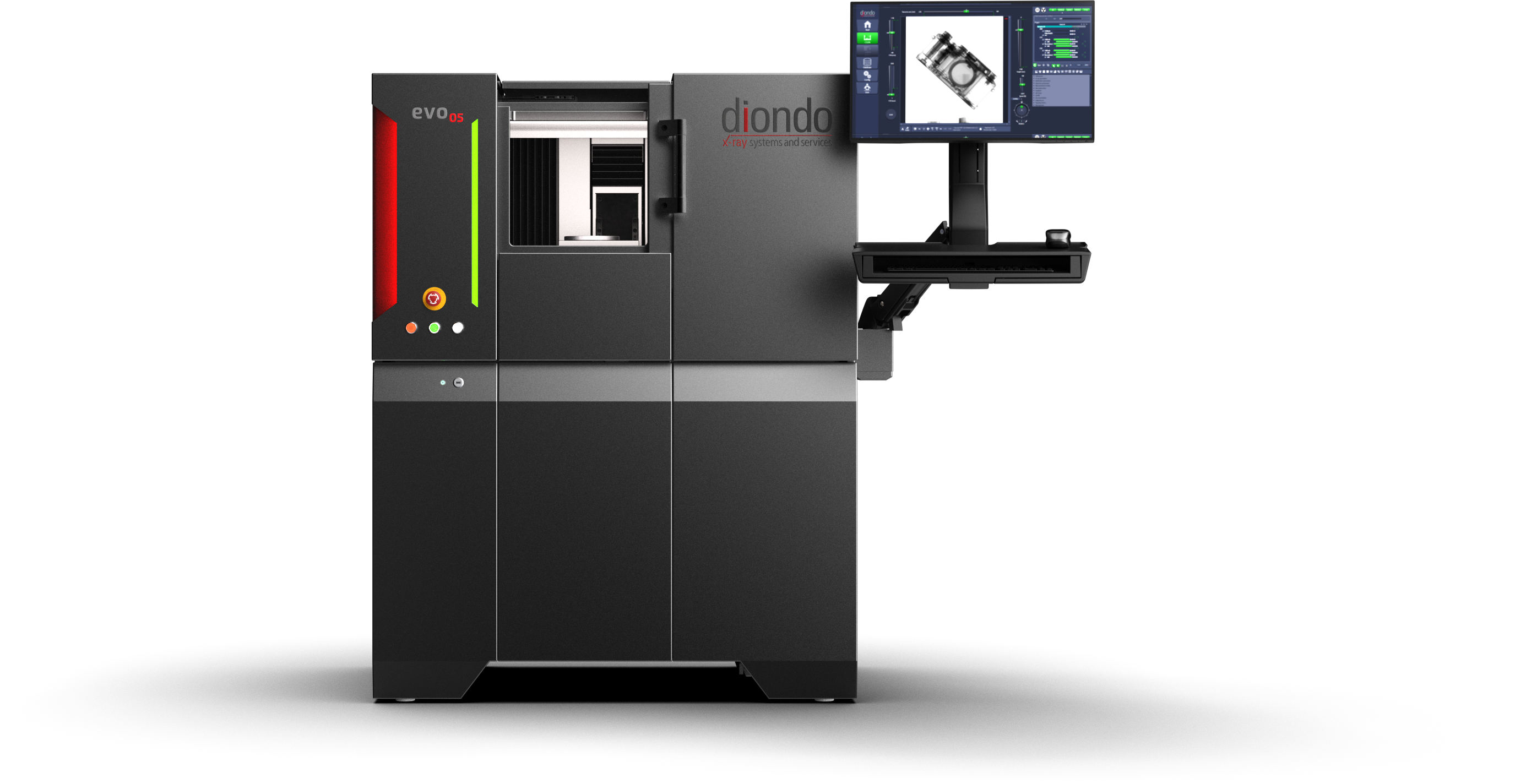

diondo evo05

User-friendly CT system for advanced measurement & inspection tasks

Computed tomography is the ideal solution for most inspection tasks. It is used in research and development, production and failure analysis. Our evo series has been specially developed to get you started with non-destructive testing. With intuitive operation, we eliminate handling errors and optimise your results right from the start. With highly competitive pricing, we reduce your investment risk and our maintenance-free concept minimizes running costs. With a large inspection area in small footprint, we create flexibility for your tasks while finding space everywhere.

Highlights

-

Outstanding Detector

with 3K resolution and 17“ size, it brings class-leading performance to your inspection lab.

-

Powerful X-Ray source

A 150 kV microfocus source enables the scanning of a wide range of samples: from plastics and organics to composite materials and light alloys.

-

Complete multiple inspection tasks in a single scan

You can digitalize complex surfaces, perform dimensionally accurate reverse engineering, or effortlessly take a look inside.

Versatility

Variable magnification and sample height. The evo 05 adapts to your test objects, giving you flexibility. Motorized axes make it easier to position objects and focus on the sample“.

Ease of use

The design and workflows in the software are tightly matched to each other and guide you quickly and easily to the result.

Return on Investment

We deliver the system as a „plug & play“ model, with minimal installation needs, so that you can get started right away after a short training session. The entire system is designed to be maintenance-free over its entire service life - no annual service costs for you!

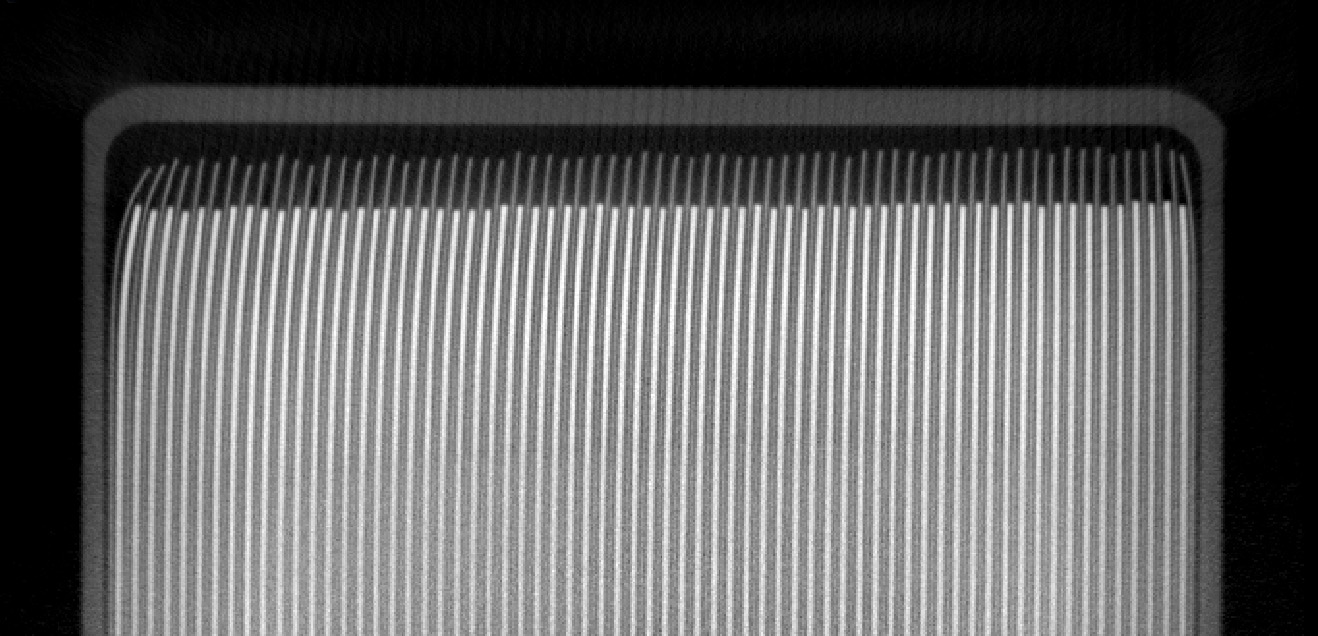

3K Detektor

The evo 05 employs the detector of a much larger system and delivers class-leading performance: high contrast 3K resolution on a 400 x 400 mm sensor surface is unrivalled in the compact class.

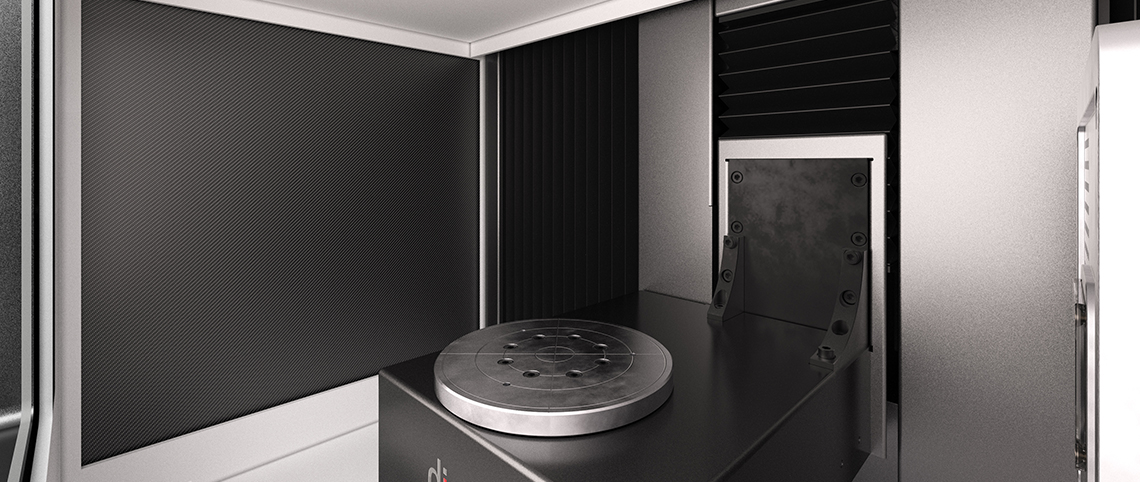

Motorized Axes

The compact design conceals a fully-fledged manipulator with magnification and height axis. This allows you to conveniently capture a wide variety of objects and always at the highest resolution.

150 kV Microfocus Source

The sealed microfocus X-ray source is an endurance runner with no maintenance intervals and is powerful enough even for high-density metallic objects. Microfocus with down to 5 µm focal spot gives you the edge in detail detectability.

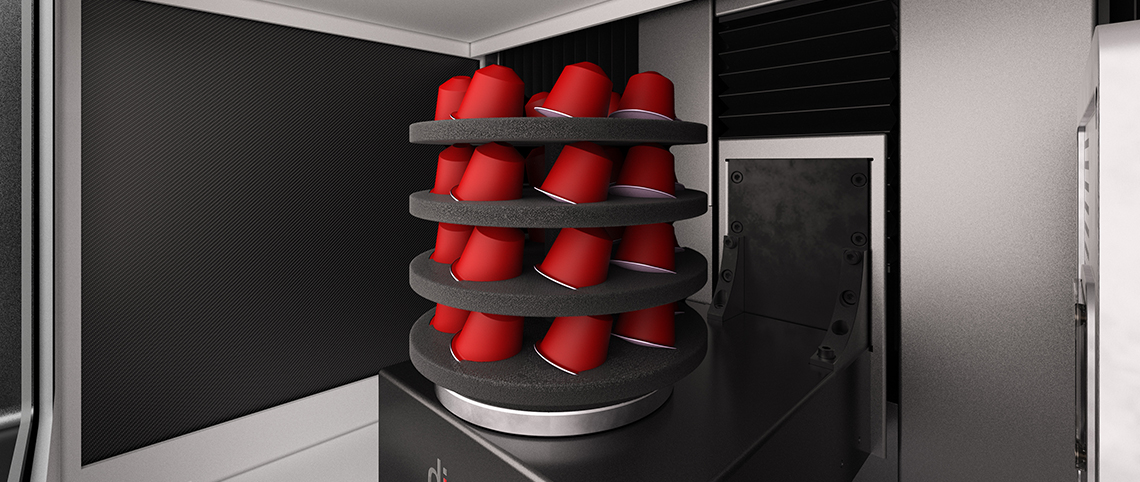

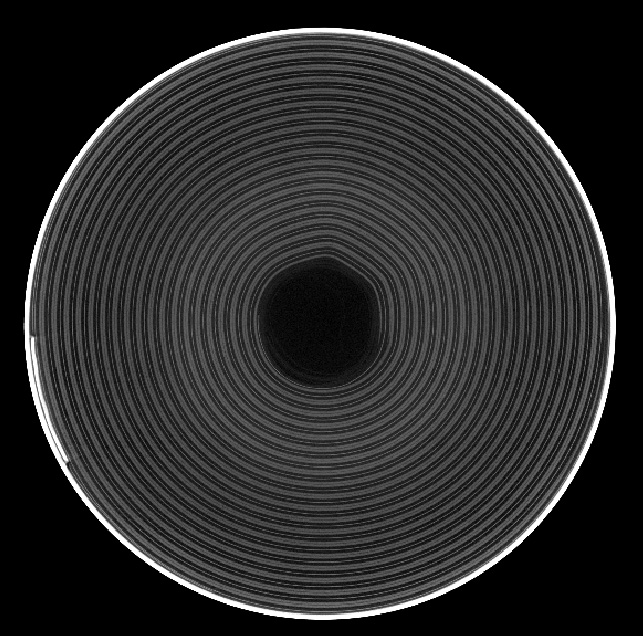

High resolution and high throughput in a single device

Thanks to its variable magnification axis, the evo 05 gives you the choice: either scan individual objects with maximum resolution or inspect numerous samples at the same time. Thanks to its unique full frame detector, fully loaded sample holders fit into the X-ray cabinet and are time-efficiently digitized in a single scan.

There is plenty of space for a variety of mounting fixtures on the sturdy turntable: diondo stacking towers and customised printed test part holders are also part of our product portfolio.

Expand your testing capabilities

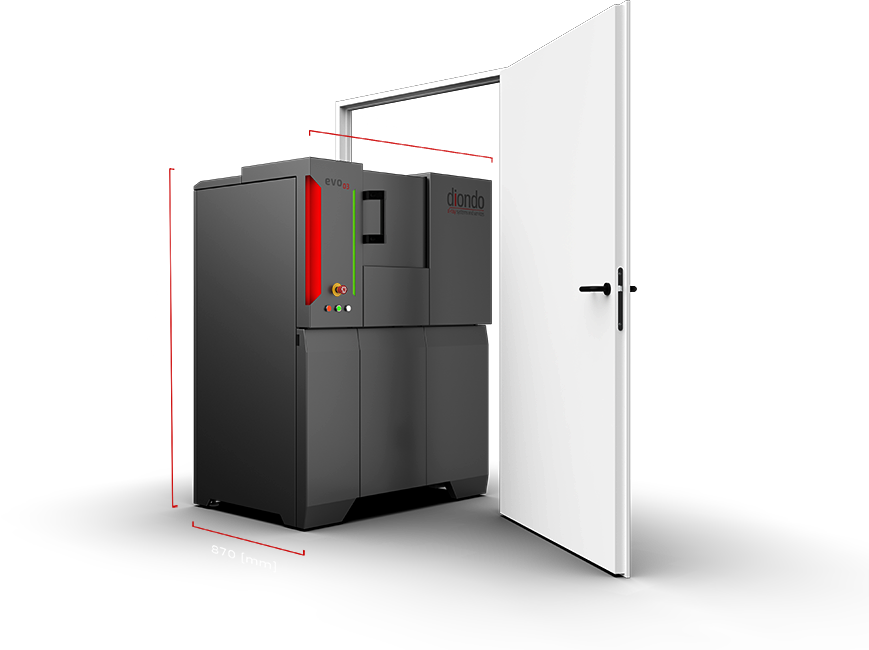

Compactness

The system is the smallest in our product family with a footprint of 1.1 m2 and can therefore easily also be positioned in smaller offices, laboratories or directly next to production equipment.

Applications

Application Areas

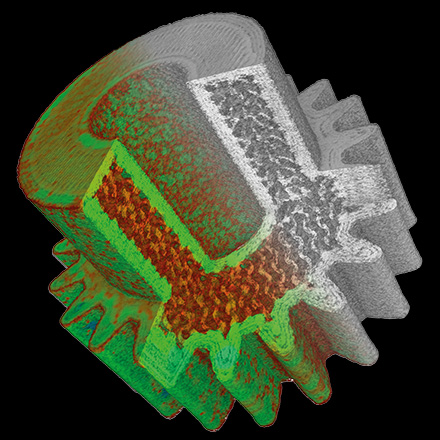

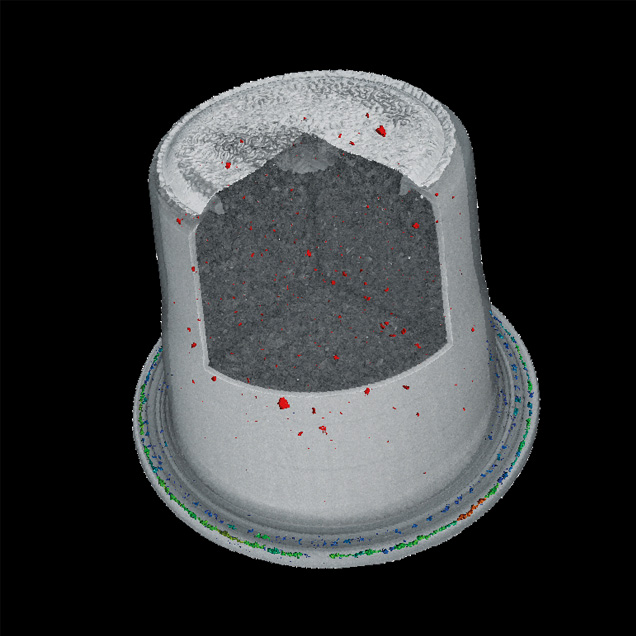

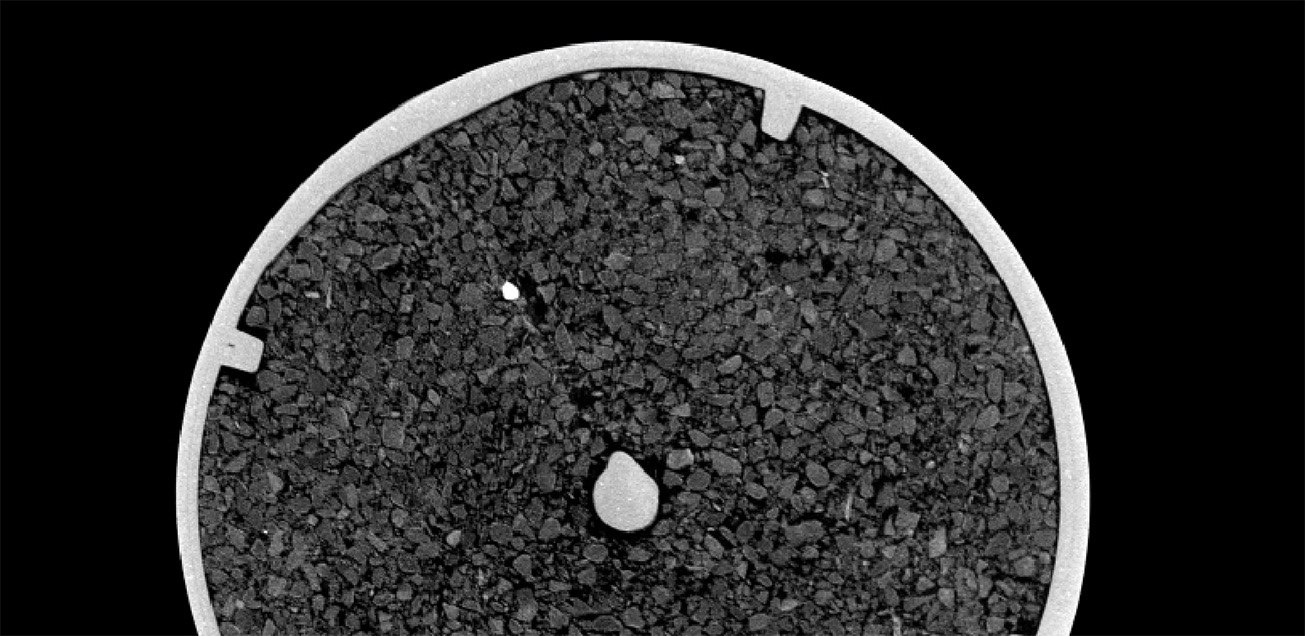

Metallic Components / Additive Manufacturing

The quality control of additively manufactured components plays an important role, as the components are often subject to high safety standards in the automotive and aerospace sectors despite weight reductions.

Aluminium parts or small metallic components with higher density, such as the additively manufactured aluminium samples shown, can also be reliably inspected.

Battery Inspection

Our unique combination of precise microfocus X-ray beam and high-resolution detector provides razor-sharp and detailed insights for the growing battery market. To enable automated inspection of even the thinnest layers, the evo05 delivers maximum image quality.

Quality control in the food and pharmaceutical industry

Thanks to its high resolution, the EVO 05 CT system can detect even the smallest foreign bodies. In addition, low-contrast fillings can be checked for homogeneity and material distribution while ensuring the dimensional accuracy of the product.

Specifications

|

Sealed Microfocus X-ray Source |

|

|

X-ray Tube Voltage |

40 bis 150 [kV] |

|

X-ray Tube Current |

10 bis 500 [μA] |

|

Maximum Output |

75 [W] |

|

Minimal Focal Spot Size |

≤ 5 [μm] |

|

Focus-Detector-Distance |

600 [mm] |

|

Scan Volume, maximal |

Ø 270 x 170 H [mm] |

|

Sample Weight |

5 [kg] |

|

Voxel Resolution |

≤ 10 [μm] |

|

System Dimensions |

L 1.260 x B 870 x H 1640 [mm] |

|

System Weight |

1.3 [t] |

|

3K Digital Flat Panel Detector |

|

|

Active Area |

417 x 417 [mm²] |

|

Active Matrix |

3.000 x 3.000 [px] |

|

Energy Range |

40 bis 160 [kV] |

|

Pitch |

139 [μm] |

|

Dynamic Range |

16 bit |

Next Steps

Please contact us, request further information or make an appointment.

dsub

dsub d1

d1 d2

d2 d3

d3 d5

d5 d7

d7