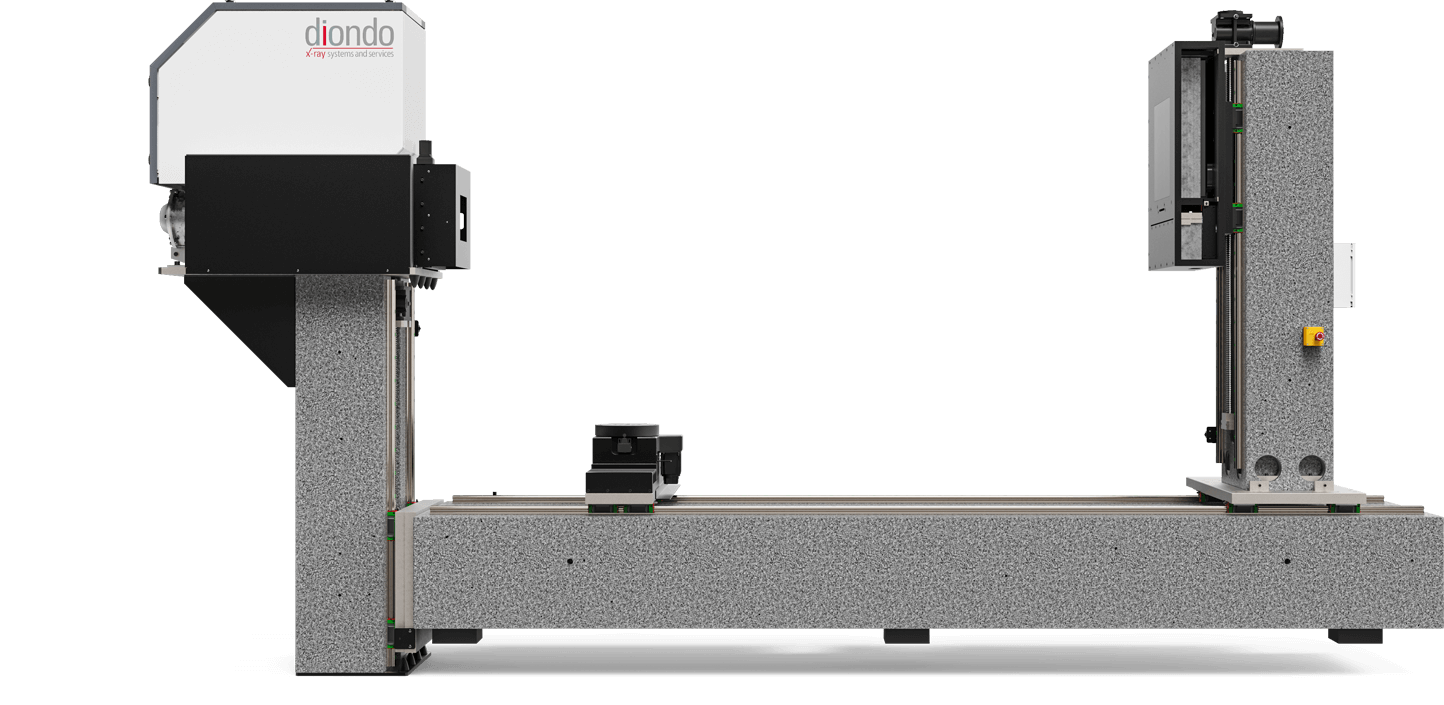

diondo d7

High-Performance Linear Accelerator CT System for Analyzing & Testing of High-Density Components

The linear accelerator CT system diondo d7 is the most powerful CT system of the product family and suited for analyses of high-density components (engine, crankcases, stators, turbine blades, etc.) from titanium, copper, steel or thick-walled aluminum. The focus of the application of such powerful CT systems are predominantly component analyses to detect any manufacturing or material defects, as well as the review of shape and wall thickness of the test objects.

Features

Linac

Performance classes 3 MeV, 6 MeV and 9 MeV,

infinitely adjustable work areas

Manipulator

Adapted to customer requirements and available in different sizes

Flat Panel Detector

High-resolution (140 µm) flat panel

detector optimized for Linac CT

Zeilendetektor

Hochauflösender (200 µm) Flachdetektor

optimiert für Linac-CT

Features

Linac

Performance classes 3 MeV, 6 MeV and 9 MeV,

infinitely adjustable work areas

Manipulator

Adapted to customer requirements and available in different sizes

Flat Panel Detector

High-resolution (140 µm) flat panel

detector optimized for Linac CT

Line Detector

High-resolution (200 µm) Line Detector

optimized for Linac-CT

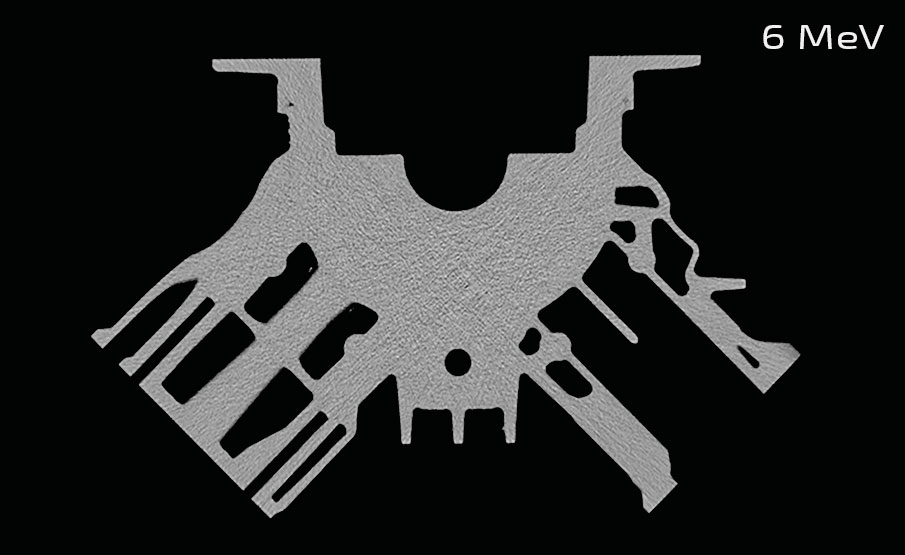

Fan beam CT of an aluminium V8 cylinder head

Why Linac CT?

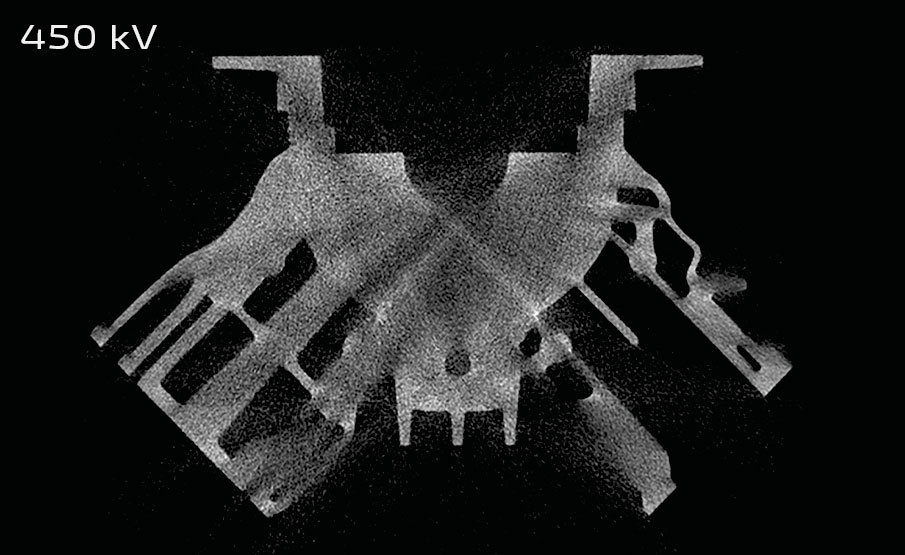

Comparison between 450 kV and 6 MeV

450 kV

Due to the immense material thickness a reliable defect detection is not possible

6 MeV

Thanks to the high penetration power not only the measurement time is drastically reduced, but also the test result allows a reliable defect analysis.

Additionally, the excellent contrast values and clear object outlines allow measurement analyses.

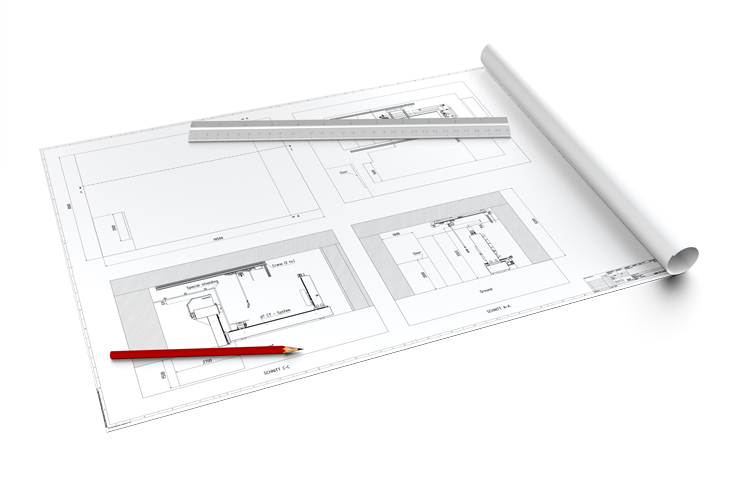

Radiation Protection Solutions

in a compact hybrid construction

Upon request, diondo offers complete radiation protection solutions designed as walk-in radiation protection room [concrete] or in a compact hybrid construction. The tailor-made radiation protection concepts of diondo are planned and implemented in close cooperation with the customer and take the specific local requirements into account.

We accompany our customers from the initial planning phase to the successful acceptance of the radiation protection of entire buildings.

Unique 1 kHz Pulse Rate

High-speed DR analyses

Due to the extremely high pulse rate and penetration power new fields of application open up.

High-speed recordings, for example, of running motors, triggering airbags and combusting fuels are possible in combination with special detectors.

In cooperation with Siemens and the Fraunhofer Institute for short-term dynamics various experimental setups have been implemented successfully.

Applications

Nothing remains hidden for these test methods

The range of applications includes everything from complex measurements of tiny components up to classical non-destructive testing of voluminous objects. The diondo d7 is used for measuring and analyzing very diverse test parts and materials such as:

- Electric mobility

[ rotors, strators,...] - Automotive

[engine blocks, cylinder heads,...] - Energy

[ turbine blades,... ]

- Air & Aerospace

[power unit components,...] - Mechanical engineering

[ high-alloy steels, cast-iron components, ...]

Do you want to learn more about our application possibilities? Are you interested in a test?

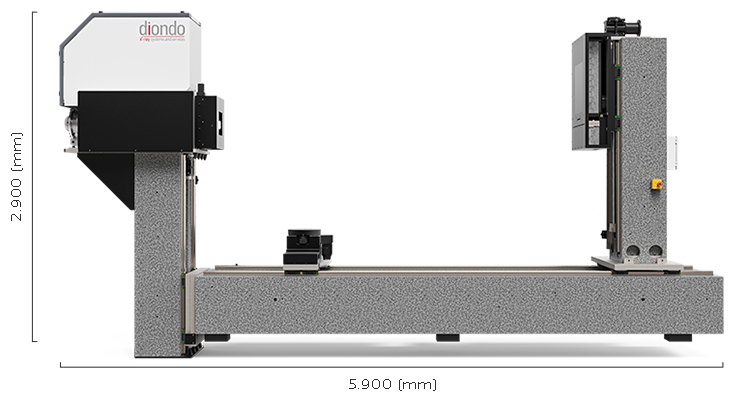

Specifications

|

X-Ray Source |

3 / 6 / 9 [MeV] |

|

|

Detector |

Flat Panel Detector 3.000 x 3.000 px, 140 [µm] |

Line Detector 3.070 px, 200 [µm] |

|

Scan Volume, maximum |

Ø 700 x 1000 H [mm] |

Ø 1000 x 1000 H [mm] |

|

Focus-Detector-Distance |

4000 [mm] |

|

|

Sample Weight |

200 [kg] |

|

|

System Dimensions |

L 5.900 x B 1.500 x H 2.900 [mm] |

|

|

System Weight |

17 [t] |

|

|

diControl Features |

DR-Function, di Scatter, Scan Enhancement, Multiline CT, Daily Check, Health Monitor, Helix CT, Batch Mode, Offset CT, Limited Angle CT |

|

|

Manipulation |

granite based, 6 / 7 axes, |

|

* optimized for Linac CT

Data in accordance with sample configuration.

Customized adjustements are available on request.

Next Steps

Please contact us, request further information or make an appointment.

dsub

dsub d1

d1 d2

d2 d3

d3 d5

d5 d7

d7