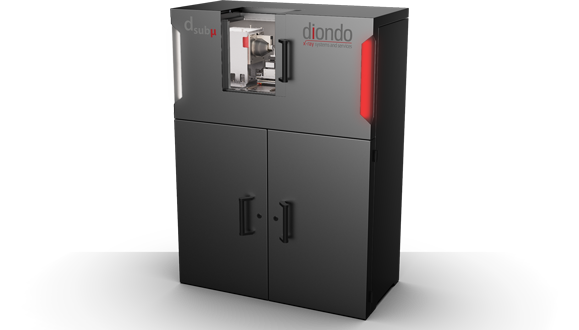

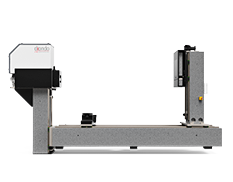

diondo dsubµ

Sub-Micro CT System for Materials Research with the Highest Resolution

The compact Sub-Micro CT System has been developed for analyzing three-dimensional structures in materials research. The sub-µ-resolution captures the finest structures three-dimensionally, which are often to be found in connection with fiber-reinforced materials or organic materials.

Features

- Innovative Detector System

with three different fields of view and sCMOS camera

- Compact Design

due to the integration of the entire periphery

- High-Precision Manipulator

due to piezo-based linear axes and air bearing rotary axis

Indirect Detector System

In contrast to conventional Micro CT Systems, which work with high magnification, the Sub-Micro CT Systems owe their high spatial resolution to their innovative x-ray camera, which allows fully automatic switching between three fields of view. The smallest of them scans your samples with 0.3 μm/voxel and the largest captures a measuring volume of up to 5 mm (1.4 μm/voxel scanning).

Applications

Nothing remains hidden for these test methods

With a maximum voxel resolution of 300 nanometers they are particularly suited for the three-dimensional analysis of micro structures. The main areas of application lie in materials research, in particular for lightweight composite materials such as carbon fiber and glass fiber composites in order to determine the density and/or the spatial orientation of the fiber. Other areas of application are metal alloys (phase fractions and shape within the metal structure), metallic and organic foams (pore size and distribution), as well as natural materials such as wood, bone and stone.

Specifications

|

X-Ray Source |

20-90 kV, max. 8 Watt |

||

|

Detector |

4 Megapixel sCMOSChip, 6.5 μm Pixel Resolution |

||

|

Voxel Resolution [µm] |

0,3 |

0,56 |

1,4 |

|

Optic |

20 x |

10 x |

4 x |

|

CT Scan Field [mm] |

0,62 |

1,2 |

2,8 |

|

Extended Scan Field [mm] |

1,1 |

2,1 |

5,0 |

|

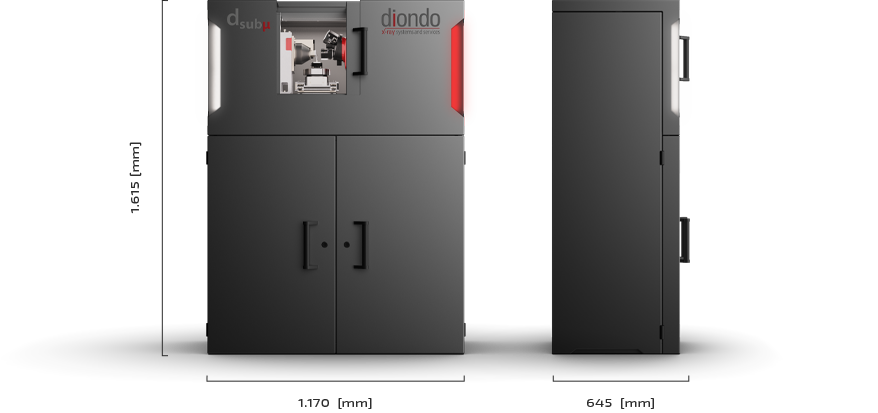

System Dimensions |

L 1.170 x B 645 x H 1.615 [mm] |

||

|

System Weight |

890 [kg] |

||

|

Manipulation |

granite based, 6 piezo-based linear axes, |

||

Next Steps

Please contact us, request further information or make an appointment.

dsub

dsub d1

d1 d2

d2 d3

d3 d5

d5 d7

d7